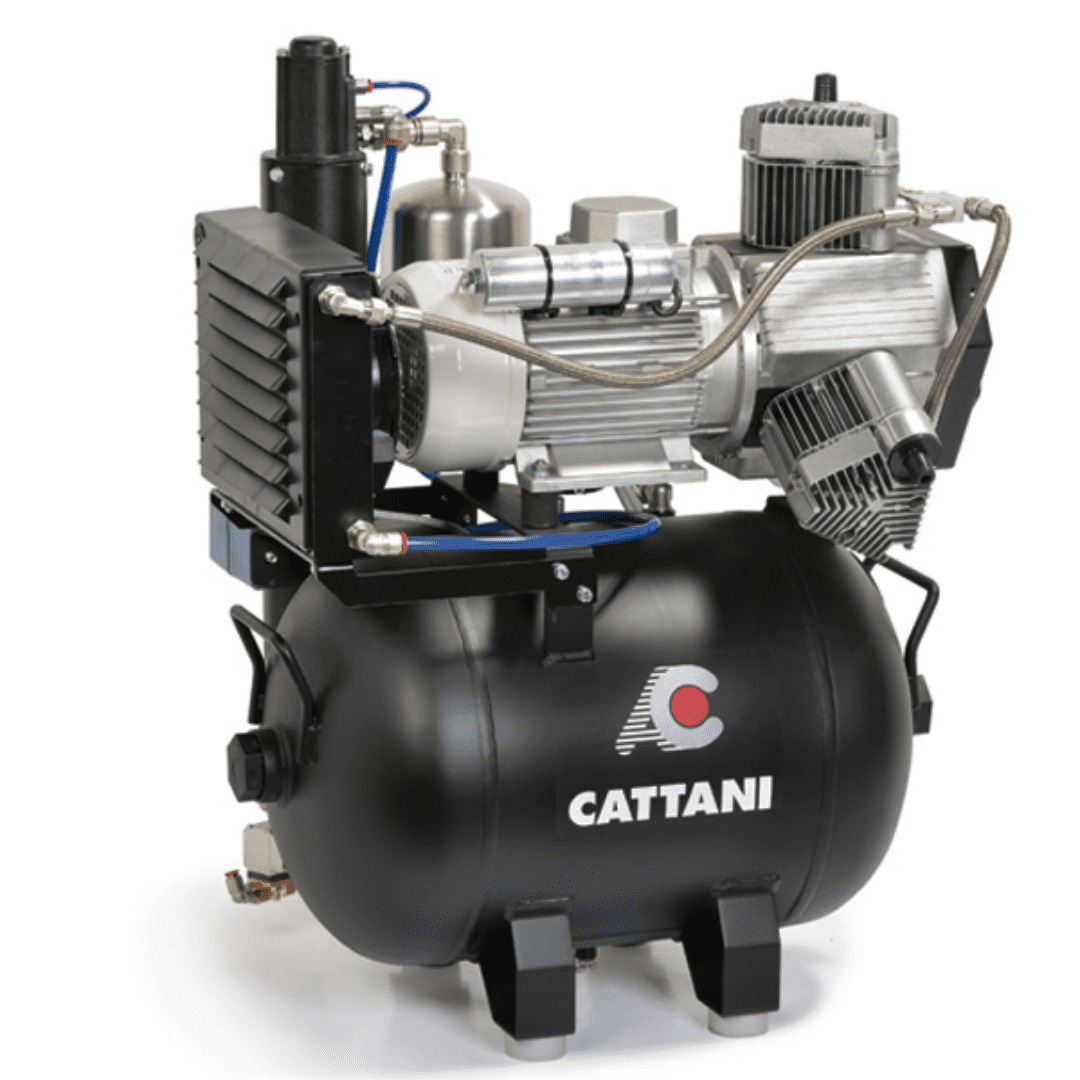

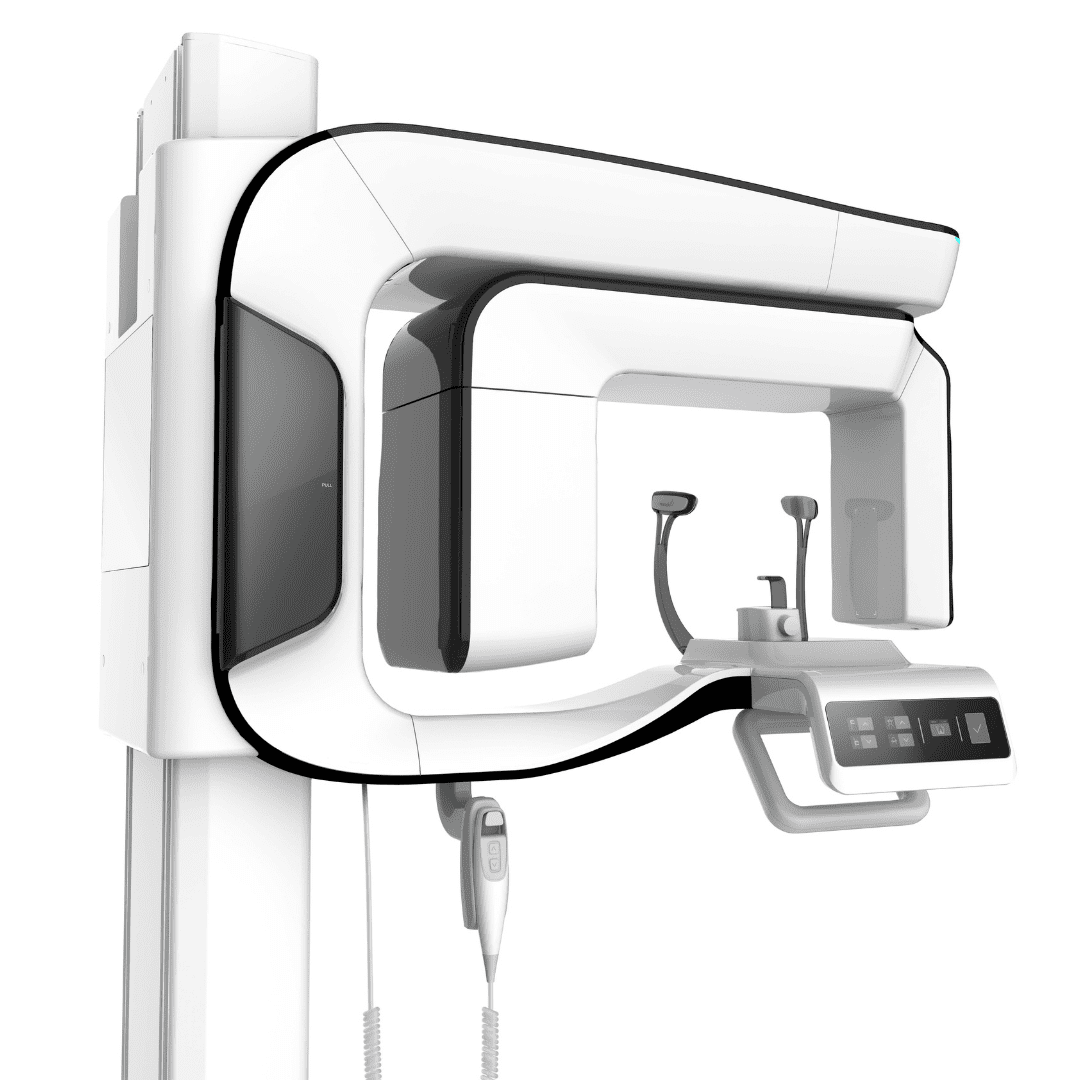

Our Products

We offer products based on experience and unbiased knowledge working with world leading dental equipment manufacturers.

Being independent we supply products that we know are of the best quality to suit your needs whether an individual item or for a complete surgery.