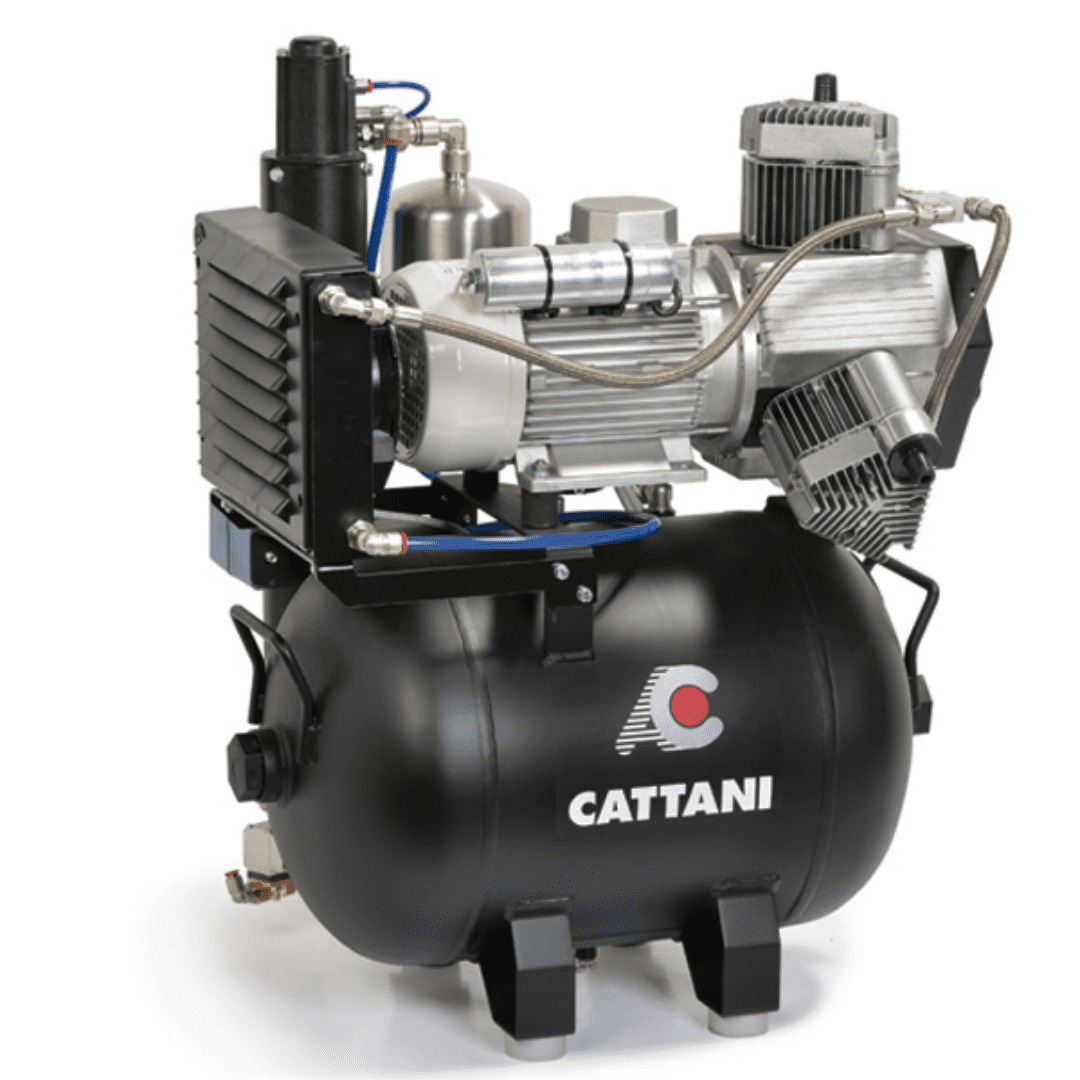

In 2018 BCAS (British Compressed Air Society) instigated changes to its legislation for dental compressors.

At Hague Dental we offer a Pressure Systems’ Compliance Written Scheme and the NEW Pressure System Inspections (PSI’s) in line with the Pressure Systems Safety Regulations 2000 (PSSR) for Dental Compressors. The PSI replaces the old PVI (Pressure Vessel Inspection).

When it comes to your annual PSI testing and inspection, which now needs to be carried out annually as part of the service, our team of PSI-qualified engineers will do everything required to make sure your compressors and autoclaves receive BCAS certification.

In addition, BCAS quotes: “Amongst the provisions of the 19 Regulations there are requirements for a written scheme of examination and consequently an examination in accordance with that written scheme. The equipment to be included shall be all protective devices and every pressure vessel in which a defect may give rise to danger. In addition, those parts of the pipework in which a defect may give rise to danger shall be identified in the scheme.”

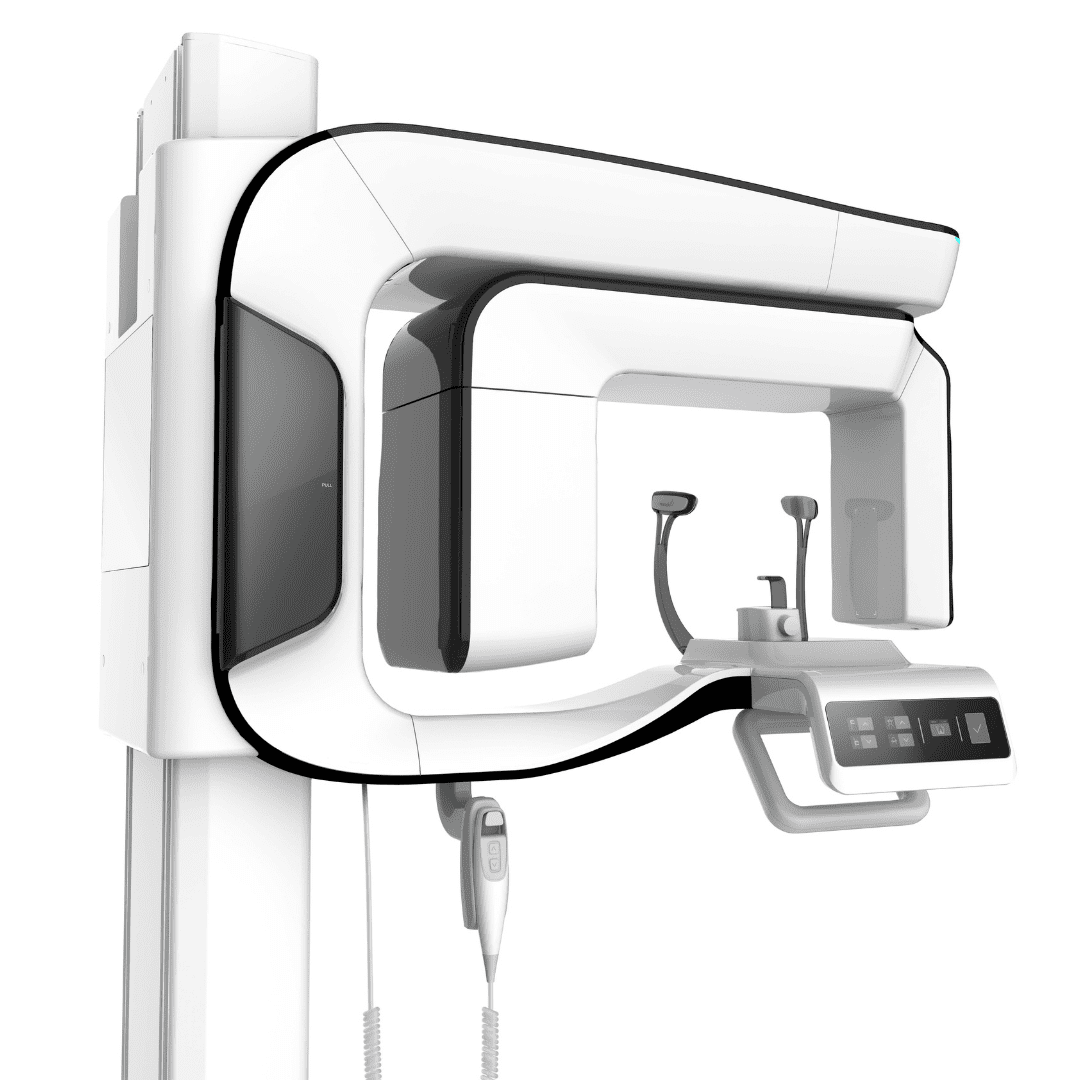

Hague Dental Engineers are qualified and experienced to repair, service and validate a full range of equipment to support your practice and to keep you up and running. Whether you need an emergency repair, an engineer to install a new piece of equipment, or its time for your annual service, we’d be delighted to help.

Supporting surgeries and clinics in Bedfordshire, Berkshire, Buckinghamshire, Cambridgeshire, Derbyshire, Dorset, Essex, Gloucestershire, Greater Manchester, Hampshire, Hertfordshire, Kent, Lancashire, Leicestershire, Lincolnshire, London, Middlesex, Norfolk, Northamptonshire, Nottinghamshire, Oxfordshire, Rutland, Shropshire, South Yorkshire, Suffolk, Surrey, Sussex, Warwickshire, West Midlands, West Yorkshire, Wiltshire, and Worcestershire.