Keeping your dental practice safe and fully compliant requires more than having a dental autoclave on site. It’s about ensuring that every sterilisation cycle delivers reliable results. As scrutiny over infection control increases, regular autoclave calibration emerges as a necessity that forms the backbone of effective sterilisation and ensures your practice meets the mandatory CQC and HTM 01-05 standards.

Why Autoclave Calibration is so Important

Regulators, such as the CQC, demand rock-solid proof that all autoclaves perform flawlessly every time. Autoclave calibration is fundamental: it verifies that temperature and pressure readings are accurate and that effective sterilisation is achieved as intended.

Regular calibration minimises risk, protecting both your patients and professional reputation.

Meeting CQC and HTM 01-05 Demands

To satisfy healthcare regulations, periodic validation of decontamination equipment is essential.. HTM 01-05 represents the gold standard for dental decontamination and thus ties directly to autoclave validation. Without accurate calibration based on robust testing, even top-quality dental autoclaves may not meet these requirements.

Failure to comply risks failed inspections, potential shutdowns, and, most worryingly, exposure to safety breach claims.

Understanding Autoclave Validation and Its Role

Autoclave validation is a rigorous, documented process that ensures every component of your autoclave is functioning properly. The engineer conducts:

- Installation checks (Installation Qualification) to ensure correct setup

- Real-world testing (Operational Qualification) to confirm proper function

- Repeated use with biological indicators (Performance Qualification) to demonstrate effective sterilisation every time

This isn’t just a bureaucratic exercise in ticking boxes. Regulations require annual or manufacturer-recommended schedules to ensure compliance, maintain current documentation, and identify issues before they threaten safety.

Expert autoclave calibration services, as offered by Hague Dental Supplies, execute this life-cycle approach across the full suite of dental practices’ needs.

Dental Autoclaves: Today’s Technology and Tomorrow’s Expectations

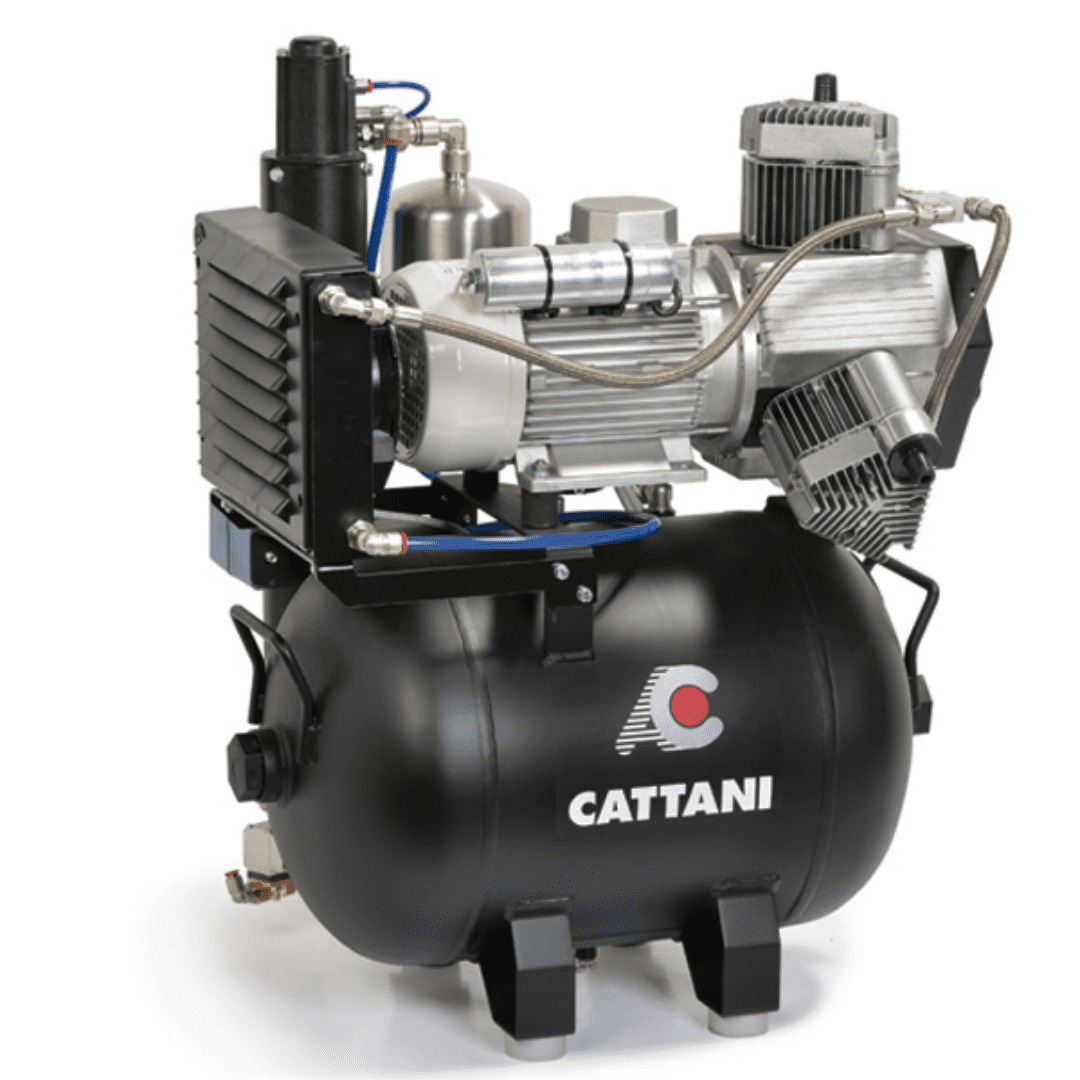

Modern dental autoclaves, such as the renowned W&H autoclave series, enhance efficiency, traceability, and safety in dental practices. But even the best equipment can fail without calibration.

Regular testing maintains optimal sterilisation cycles while extending your autoclave’s lifespan, ensuring your capital investment continues to pay dividends.

What Do Premium Autoclave Calibration Services Include?

The best autoclave validation services cover:

- Precise, UKAS-traceable calibration of temperature and pressure sensors

- Signed documentation to prove compliance with CQC and HTM 01-05

- Full validation protocols tailored to your model and daily loads

- Transparent reports to support staff training and audit preparedness

- Proactive advice about the latest standards and best sterilisation practice

Partnering with an experienced provider ensures that all protocols are met and that peace of mind is part of your annual service contract. This is non-negotiable for any busy dental practice.

Why Calibration and Validation Deserve Your Attention

Calibration and validation underpin everything, from day-to-day safety to long-term compliance. Consider these key points:

- Uncalibrated autoclaves might not reach sterilising temperatures, risking cross-contamination.

- Incomplete validation records can jeopardise CQC inspection outcomes.

- Proper calibration sustains equipment warranties and extends working life.

With evolving guidance, especially as new models like the advanced W&H autoclave enter the market, practices must stay ahead by engaging with trusted validation specialists who offer the most current, CQC-compliant autoclave validation services.

Secure your peace of mind, bolster safety, and pass every inspection with confidence. Book your autoclave calibration and validation without delay.