Repair or Replace - At what point does repairing become throwing good money after bad?

In these times of ever-tightening belts and prudent financial planning, it has never been more important to stop and take stock of your capital equipment portfolio. Forward planning of future capital dental equipment purchases should be based upon the previous year’s performance and downtime. Downtime is the enemy of all dental practices, replacing lost revenue can be an uphill struggle especially when patients are applying the same rules of prudence as you are. If an item has been constantly underperforming and keeps letting you down ask yourself the question – repair or replace?

Life span of dental equipment

It is very tempting to pay to have a suction pump reconditioned, but if the machine is eight years old and has been showing signs of repeated failure, what will the future hold for this item even after reconditioning? Every item of capital equipment has a life span depending on usage. Most reputable manufacturers of dental equipment conform to all current regulations and many carry lengthy warranties to offer the end-user peace of mind if an item should fail.

Importance of a trusted experienced dealer

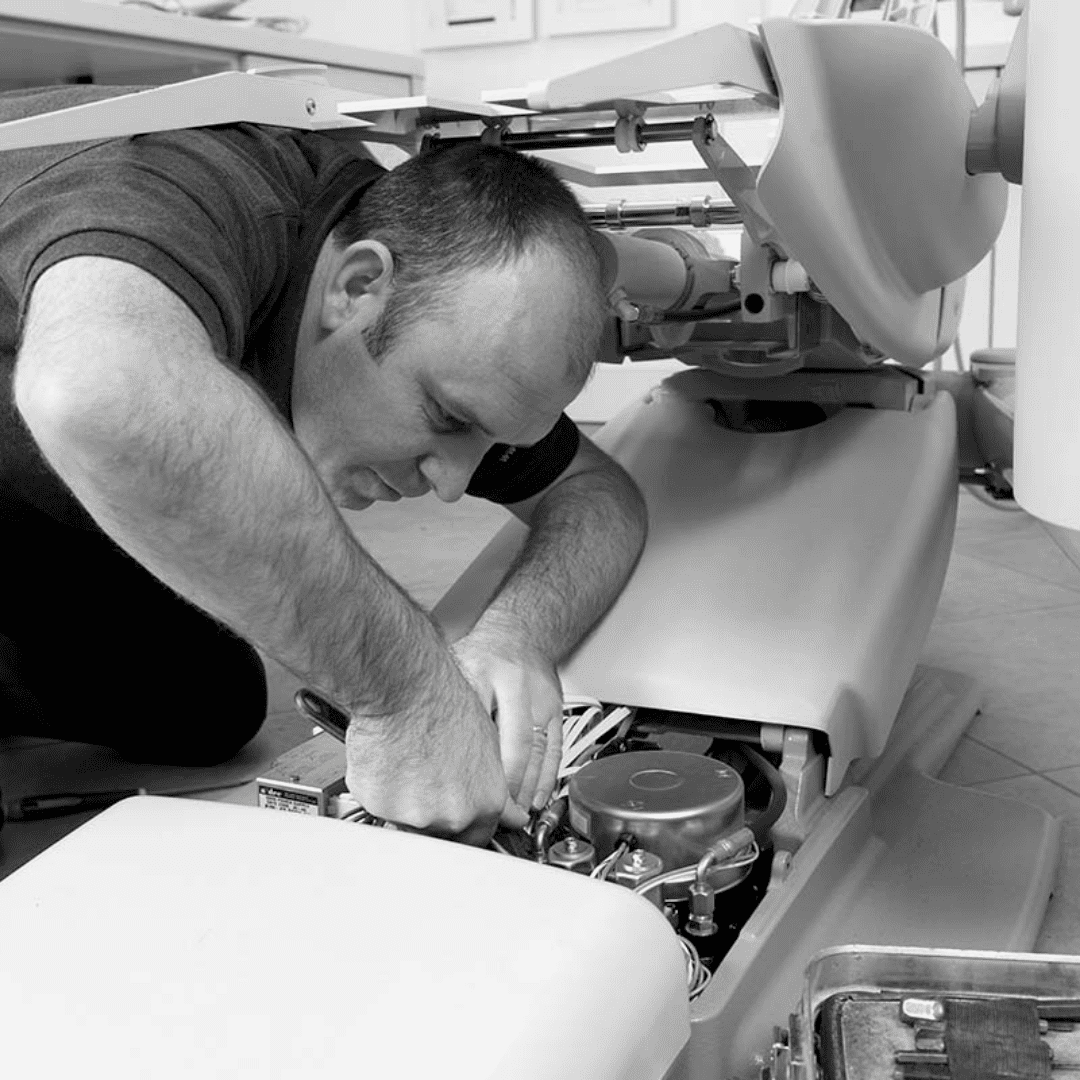

Your relationship with your equipment dealer/service partner is vital. Annual maintenance by a factory-trained technician can extend the life of capital equipment considerably. Most well-trained technicians will feel comfortable to give you advice based on their experience and know when to advise you that the costs of repairing are worth you considering a new replacement. Whether you take their advice is entirely down to you, but remember a day’s lost revenue can amount to £1,500 or more and as discussed before this revenue is extremely difficult to make up.

Audit time

Our advice to any practice would be to set aside time to do a full capital equipment audit. The best time to do this is at the start of your financial year when you are planning your budgets for the year ahead.

Start a register of all your large capital equipment items, ask all the staff who use the equipment their opinion of how the item has performed in the previous year, and their opinion on whether to repair or replace. Then, if you have had more than one day’s lost surgery time due to a breakdown of a capital equipment item log it in your register as a possible item at risk of replacement.

Some practices use a traffic light system where reliable items are coded green, intermittent amber and red for constantly failing. Good financial planning is aided by having a good early-warning system for failing items, which means capital budgets can be set aside for equipment replacement. Many of you will already have experience with CQC inspections and realise that record keeping is now mandatory and not voluntary. If you produce a capital equipment directory make sure it has make, model, serial number and an up-to-date record of servicing. The more accurate this directory is the speedier the audit process will be.

Trouble free ownership

I will leave you with the thought that for trouble-free ownership, how your staff use and maintain the equipment is vital. The better trained the staff who use and maintain your equipment, the longer the life span. So make sure your equipment supplier is not just a box shipper. It must commit to training your staff and commit to supporting you for the life of the product. The next time you have a major failure of capital equipment, ask yourself when did that item last fail and how much did it cost us to fix? Then hopefully this article may spark the repair or replace discussion.

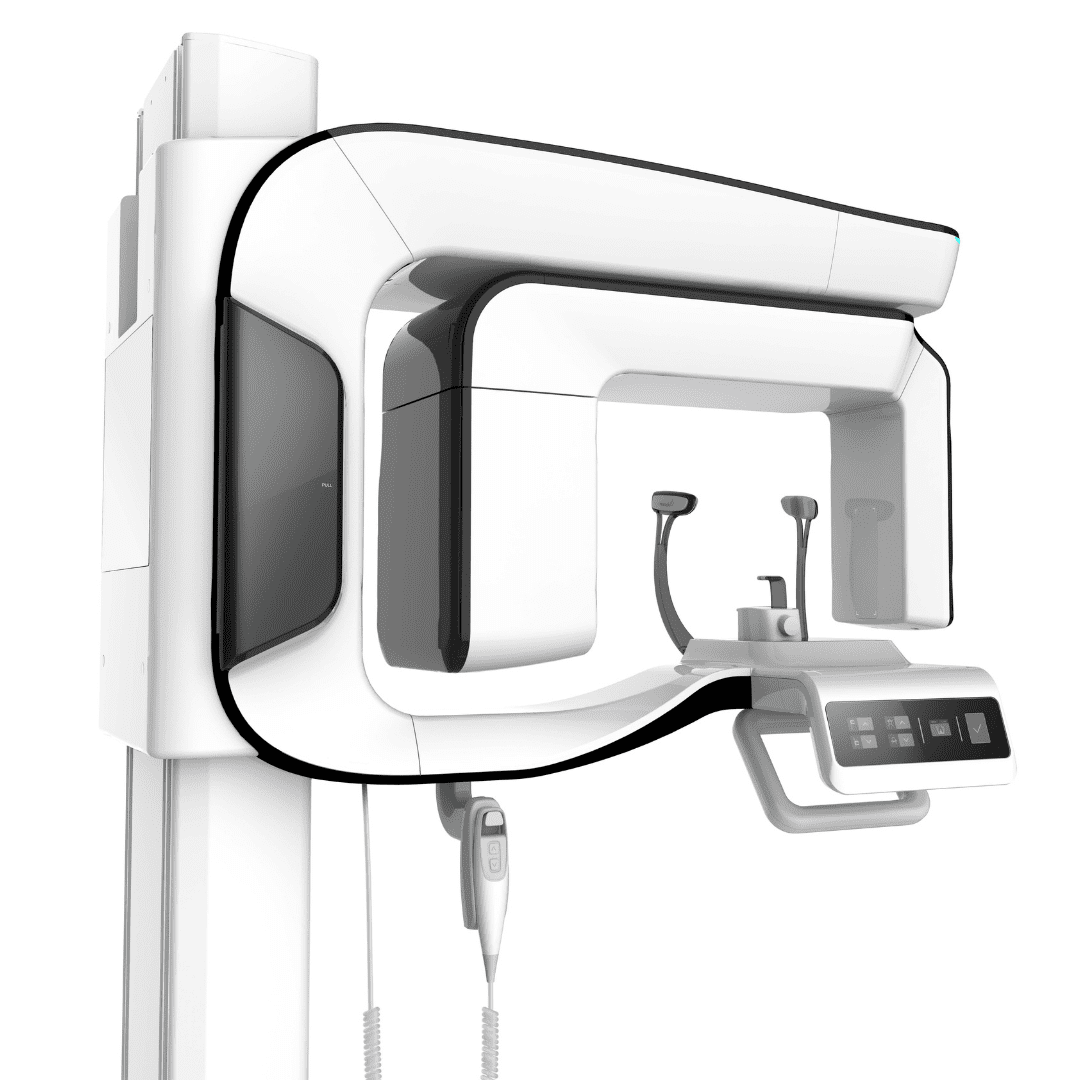

The following pages can help you repair or replace existing equipment of yours.

Dental Equipment Solutions for your Practice | Hague Dental Supplies